Beyond Tapeout: Opening the Dark Side of Mask Data Preparation

News & Press

Beyond Tapeout: Opening the Dark Side of Mask Data Preparation

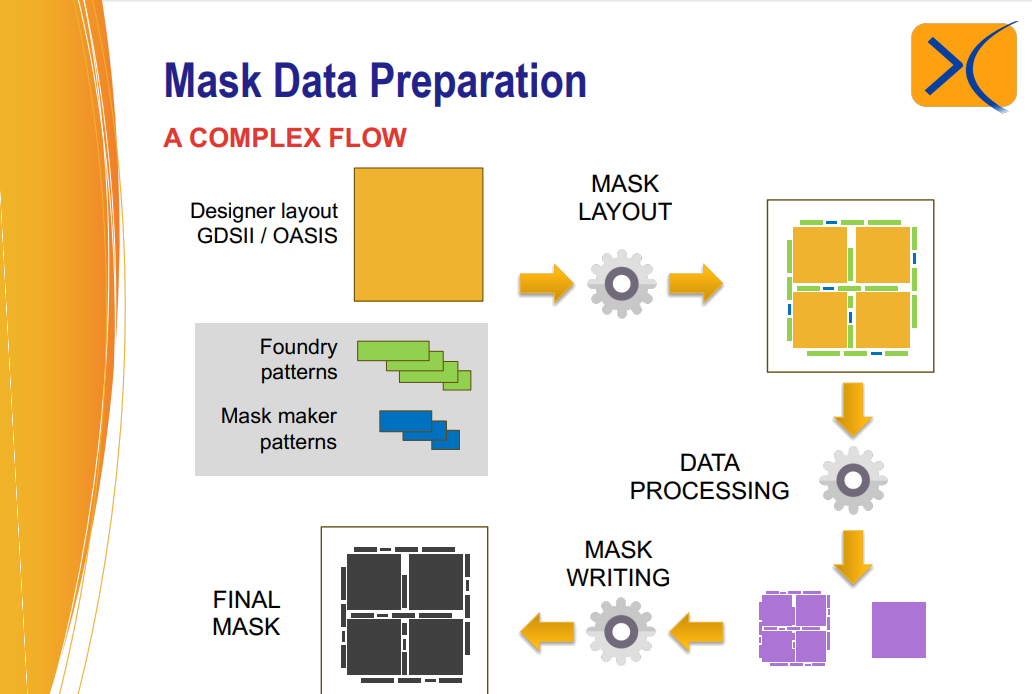

The transition from chip design to manufacturing is often seen as seamless, but mask data preparation (MDP) remains complex and under-automated. This paper explores MDP challenges and how XYALIS solutions close automation gaps to improve scalability and efficiency.

Abstract

The transition from design completion (tapeout) to chip fabrication is often presented as seamless, almost magical. However, this perception overlooks a critical reality: a physical mask set must first be manufactured to transfer the layout image onto silicon. Mask data preparation (MDP) remains something of a black art, presenting intricate technical and economic challenges that demand advanced expertise. While the industry has invested heavily in automating computationally intensive processes like Optical Proximity Correction (OPC) and fracturing, mask layout generation remains significantly under-automated, creating bottlenecks and scalability limitations. This paper examines the critical challenges in mask data preparation and demonstrates how XYALIS solutions address these automation gaps to streamline the path from chip design to manufacturing.

Introduction: Unveiling the Hidden Complexity of Post-Tapeout Processing

When semiconductor chip development flows are presented, the step between chip layout and manufactured chip is often summarized by a magical arrow. This tends to trivialize the transition from the GDS or OASIS® layout to the fabricated chip, which involves numerous sophisticated steps, with mask data preparation representing one of the most technically demanding yet underappreciated phases.

Despite significant industry investments in automating critical processes like Optical Proximity Correction and fracturing, mask layout generation remains an underserved area. Many organizations continue to rely on manual or semi-automated processes for mask layout—workflows that often date back decades—creating inefficiencies, introducing error-prone operations, and limiting scalability with increasing design complexity.

At XYALIS, mask layout is central to our expertise and innovation. We recognize that masks serve as the vital link between chip design and physical manufacturing. The data contained within these masks directly inform the mask and silicon production process, making thorough mask data preparation essential for achieving successful manufacturing results.

Read the full article here.

By Frederic Brault, CTO, XYALIS